| PRODUCT RANGE | LOW to MEDIUM TEMPERATURE | HIGH TEMPERATURE | |

|---|---|---|---|

| THERMAL CARRIER | Superheated Water / Steam / Thermal Oil | Thermal oil | |

| TEMPERATURE | 155°C to 210°C (inlet) / 50°C to 130°C (outlet) | 310°C (inlet) / 90°C to 180°C (outlet) | |

| THERMAL POWER | 1000 kWth to 4000 kWth / 4000 kWth and above | 3000 kWth and above | |

| RATED CAPACITY | 140 kWe to 560 kWe / 560 kWe to 7000 kWe | 600 kWe to 7000 kWe | |

| GROSS EFFICIENCY | 14% / 14% to 16% | 22% to 24% | |

| COLD SOURCE | ACC* / ACC ou WCC* | ACC ou WCC | |

| FLUID | R1233zdE / R245fa / R1233zdE / R245fa / Alkanes | Cyclopentane |

Gas Engines

Waste heat recovery is a highly profitable investment opportunity that significantly increases the efficiency of all gas engines. For the first time, the patented Clean Cycle ORC technology allows each gas engine to independently generate electricity from the heat discharged from its own stack, without the need for costly investments.

Biogas plants, biomass plants, waste incineration plants, landfill gas plants, and wastewater treatment plants discharge a significant amount of waste heat from their gas engines through their stacks. By installing heat exchangers in parallel with the stack exhaust line, this waste heat can be converted into hot water at 155°C and fed to the patented Clean Cycle ORC turbine to generate electricity.

Biomass Boilers

For the first time, the patented Clean Cycle ORC technology enables biomass boilers of all sizes to convert their idle capacity and waste heat from the stack into electricity without requiring high-cost investments. This not only generates electricity but also allows for more balanced boiler operating temperatures.

Rather traditional ORC systems, the use of water as the heat transfer fluid eliminates any additional insurance burdens and operational risks for the operatör.

Industrial Processes

GE's patented Clean Cycle ORC technology offers a straightforward solution for waste heat recovery in any industrial setting. By employing water as the heat transfer fluid, this technology avoids the additional insurance costs and operational hazards commonly associated with conventional ORC systems. Industries such as cement, food, iron and steel, petrochemicals, and wood processing possess substantial untapped potential for waste heat recovery.

Liquid-Fueled Engines

"Waste heat recovery offers a highly profitable and efficiency-enhancing investment opportunity for all liquid-fueled engines. With the patented Clean Cycle ORC technology, for the first time, every liquid-fueled engine can independently generate electricity from its own stack heat without requiring high-cost investments.

By installing heat exchangers in parallel with the flue gas outlet, waste heat is converted into hot water at 155°C and then transferred to the patented Clean Cycle ORC turbine for electricity generation.

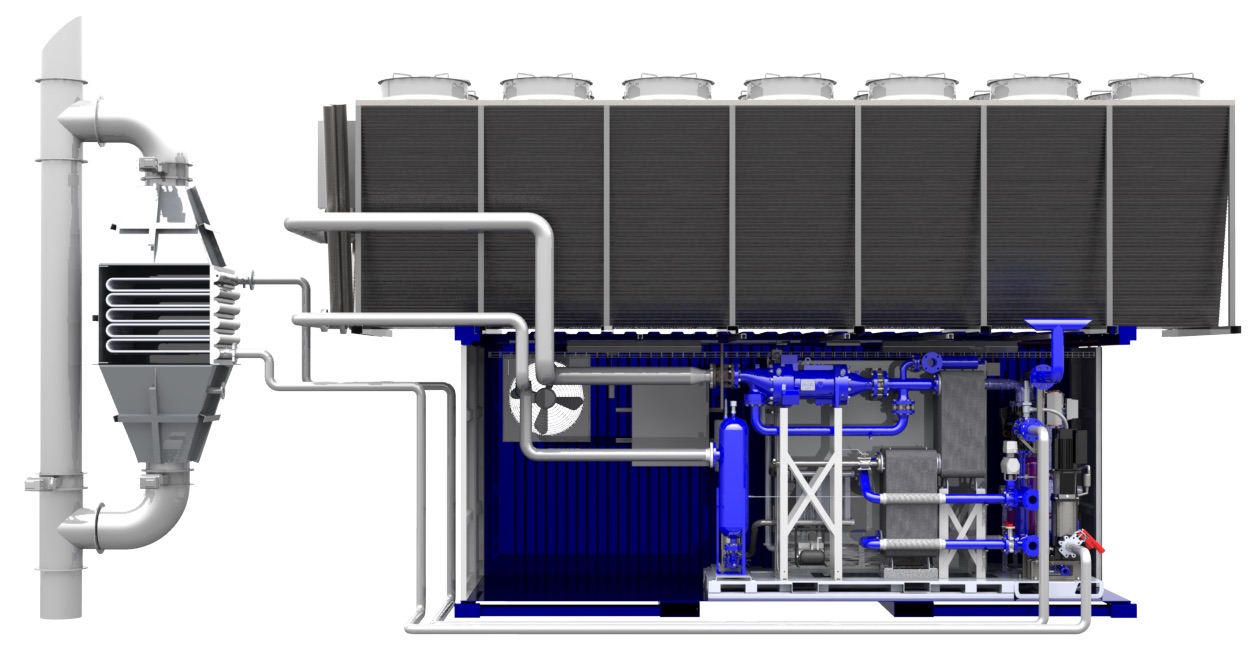

General Electric's patented Clean Cycle™ ORC Technology

The Clean Cycle™ ORC Technology, a patented waste heat recovery technology developed by General Electric (GE), is of American origin. Its most significant distinction lies in its utilization of a patented frictionless turbine technology with magnetic bearings. This enables maximum electricity generation with minimal waste heat and allows for full performance operation at thermal inputs of 1 MW and above. The patented turbine technology also allows for the use of various ORC fluids, including water, depending on the heat source.

Traditionally, ORC systems worldwide for waste heat recovery have employed axial or radial shaft turbines with high friction coefficients. General Electric (GE) has revolutionized waste heat to electricity conversion with its innovative patented Clean Cycle™ ORC Turbine. Featuring a frictionless turbine technology with magnetic bearings, this ORC system offers unprecedented efficiency and minimal maintenance requirements.